Wei GROUP

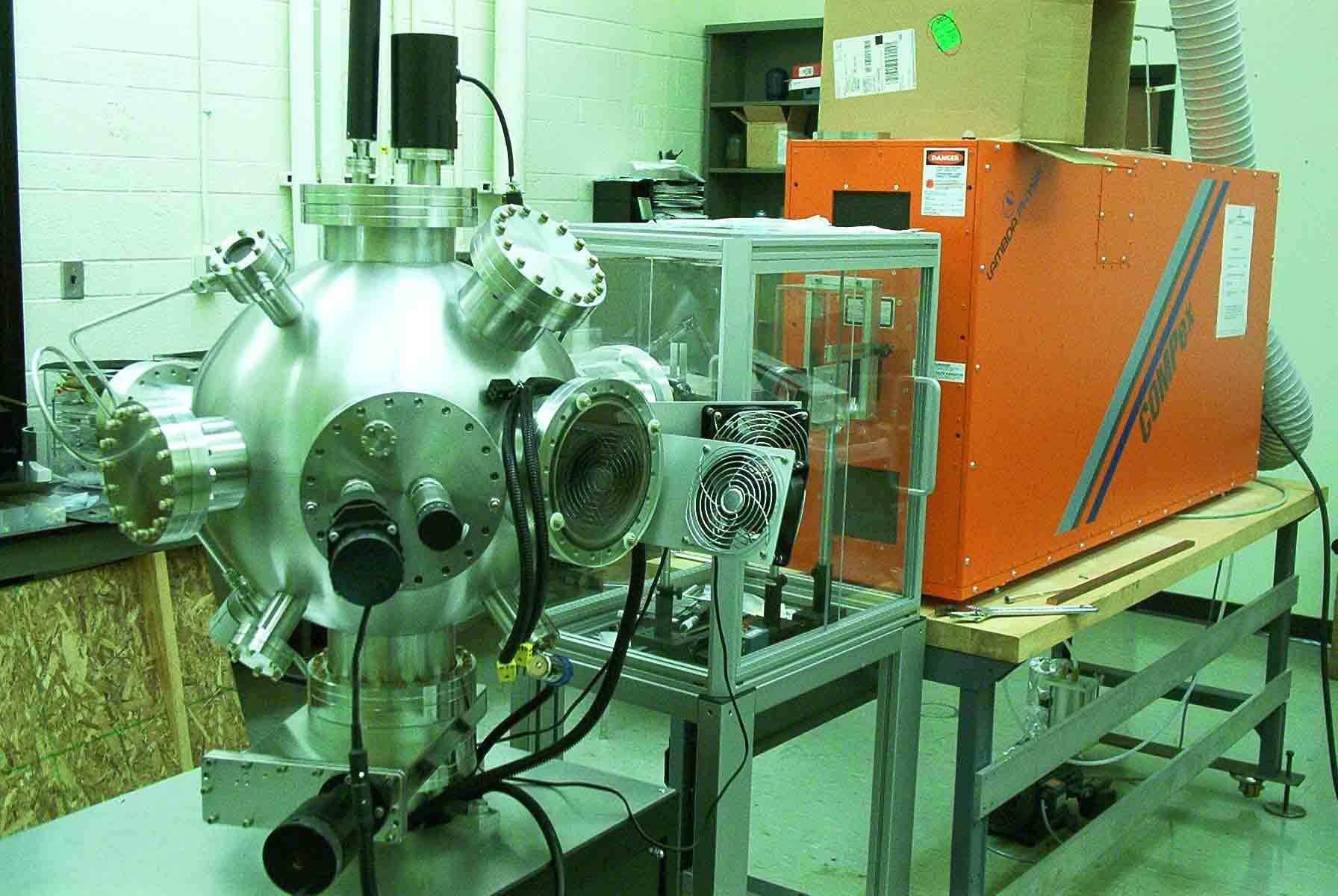

Laser Deposition Lab (MP 071)

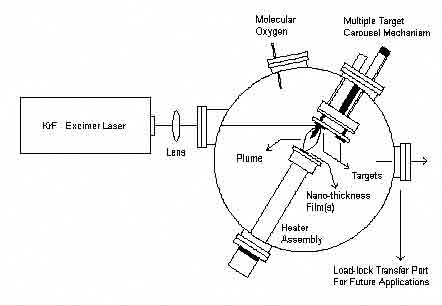

Pulsed laser deposition is a powerful technique for growing epitaxial

thin films of complex oxides, by virtue of its thermodynamic range and

experimental flexibility. It has emerged as the method of choice

for nanoscale materials research on complex oxides, particularly the

transition-metal perovskites which have very rich phase diagrams and

show a variety of correlated eletronic phenomena. These phenomena

include high temperature superconductivity, colossal magnetoresistance

and magnetoelectronic multiferroism, which may lead to a new generation

of oxide-based microelectronic devices based on complex oxides.

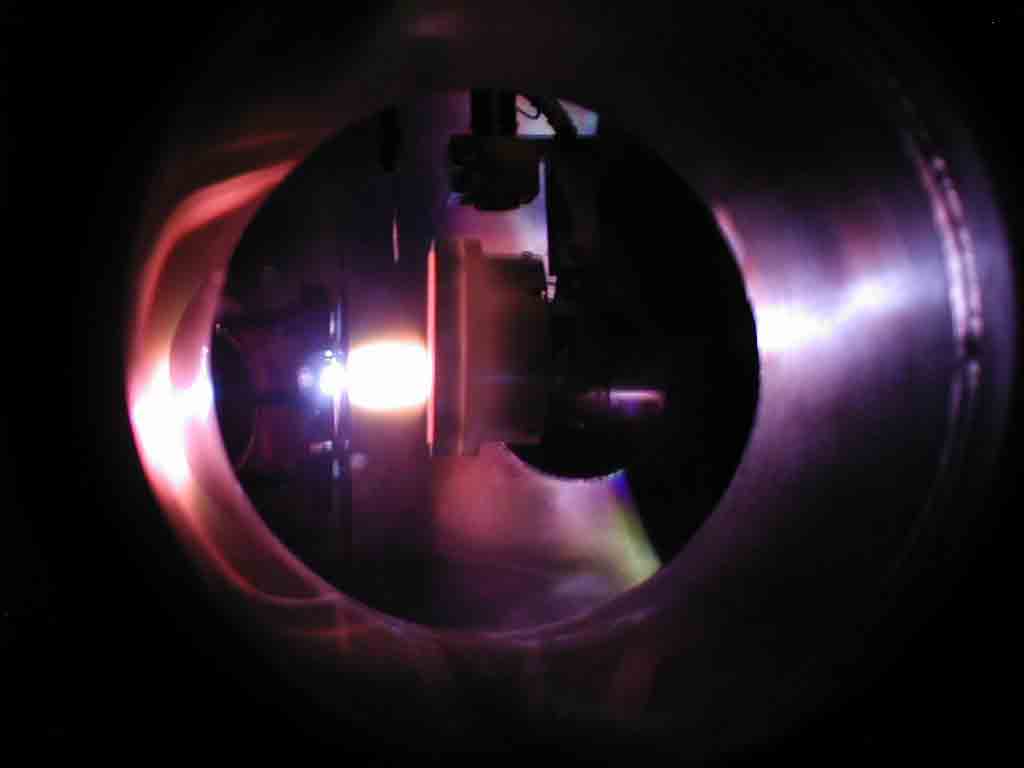

Pulsed Laser

Deposition system

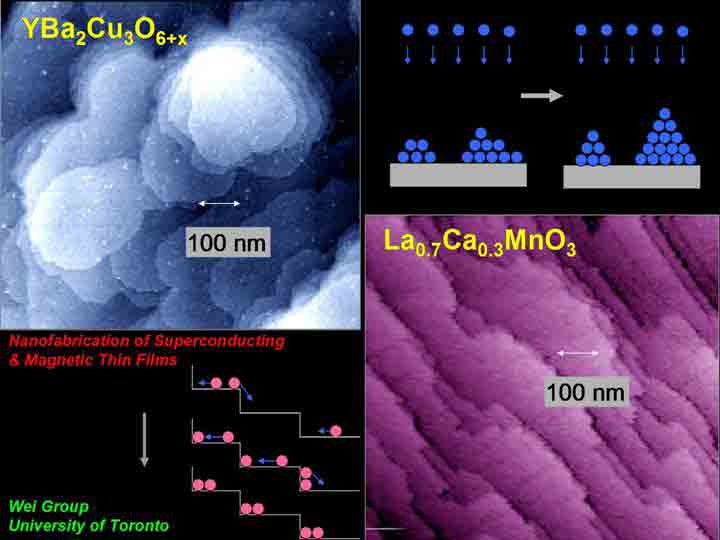

The surface

morphology of the the epitaxially grown films depends on the exact

growth mode. Two typical modes are: step-flow growth, which

lead to fishscale-like terraces; mount-clump growth, which produce

rice-paddy surface structures. The surface quality can be

characterized by imaging with either AFM or STM, with nanometer

resolution. Film epitaxiality can be confirmed using x-ray

diffraction with rocking-curve analysis. Overall film quality

depends on the material and ablation conditions, and can be optimized

through close feedback between synthesis and characterization.

For the latter, our PPMS system enables measurement of various physical

properties, such as resistivity and magnetization, versus both

temperature and magnetic field.

We are currently installing a second laser deposition system, donated from IBM T.J. Watson Research Center. This state-of-the-art system has a high-power excimer laser with adjustable wavelength, plus an ultra-high vacuum chamber which is equipped with RHEED and atomic oxygen source. The differentially-pumped RHEED gun provides real-time monitoring of the film deposition, to enable true layer-by-layer growth in unit-cell blocks approaching atomic smoothness.