ADVANCED UNDERGRADUATE LABORATORY

EXPERIMENT 32, FILM

Thin Film Interference

References updated by Barbara Chu, August 2006

Revision: March

2006 by Yi Chai

Original

By: Jason Harlow, 2006

1. Introduction

The

interference of reflected waves of light from transparent layers of material is

responsible for many beautiful phenomena in nature, such as butterfly wings,

peacock feathers and soap bubbles.

Multiple layers of thin transparent films with various indices of

refraction can be deposited on glass or metal substrates in a variety of ways

to control light. This has many

applications in science and industry, including anti-reflection coatings,

mirrors and optical filters.

Since

the discovery of the phenomenon of interference colors associated with thin

solid films, immense studies of the science and technology of thin film have

been conducted for nearly two centuries. Majority interest in this field has

been dominated by the unforeseen behaviors of solid films and the usefulness of

consequential optical properties with potential applications in mirrors and

interferometers. In particular, exploitation of the optical interference

phenomenon has led to development of instruments with tunable reflectance and

transmittance.

When thin film based mirrors are used for the purposes of

reflection and transmission, the most ideal system bears a minimized absorption

of incident light. Such systems are made possible by formation of non-metallic,

or dielectric, coated thin films, sometimes referred to as dielectric mirrors.

The process involves deposition of multilayer dielectric material onto glass

substrate. The choices of the type and thickness of the dielectric layers allow

for adjustable reflectance targeting at specific range of wavelengths. This

experiment carries out the fabrication of multilayer high reflectance

narrowband thin films by the photometric method.

2. Theory

To

investigate the optics of thin film interference, we will follow the derivation

of Fowles Chapter 4, and Hecht Chapter 9.

The general solution encompassing oblique incident light can be deduced

following the derivation of Chopra [2] page 722.

Single Layer Dielectric Thin Film

First consider the case of a single layer of dielectric

material, with thickness d and index

of refraction n, deposited onto a substrate

with index of refraction nS.

This sample is exposed to a medium with index of refraction n0, typically air. As shown

in Figure 1, when light of vacuum wavelength λ0 is normally incident on the sample, transmission

and reflection from both interfaces occur.

Figure 1. Electric and Magnetic fields across a single

dielectric layer

The boundary conditions

require that the electric and magnetic fields be continuous at both interfaces.

They yield the following equations:

First interface

![]() (1)

(1)

![]() (2)

(2)

Second interface

![]() (3)

(3)

![]() (4)

(4)

To get equations (2) and (4)

the relation ![]() was used. The phase

factors eikd and e-ikd in equations (3) and

(4) result from the fact that the wave has traveled a distance of d inside the dielectric layer; thus it

is advanced or delayed by a phase of kd,

where k is the wave number.

was used. The phase

factors eikd and e-ikd in equations (3) and

(4) result from the fact that the wave has traveled a distance of d inside the dielectric layer; thus it

is advanced or delayed by a phase of kd,

where k is the wave number.

By eliminating the amplitudes within the layer, E1

and E’1, equations (1) through (4) can be combined to yield:

![]() (5)

(5)

(6)

(6)

Equations (5) and (6) can be

represented by a matrix equation of the form:

(7)

(7)

In equations (7), r is called the reflection coefficient

with

![]()

and t is called the transmission coefficient with

![]()

finally, M is the transfer matrix and

(8)

(8)

Solving for r and t gives

![]() (9)

(9)

![]() (10)

(10)

As the result, the

measurement of the reflectance R and

the transmittance T are given by R=|r|2 and T=|t|2, respectively.

Physically, R and T indicate the proportion of light

intensity reflected by and transmitted through the dielectric system.

Question 2.1.

With ![]() , evaluate R and T for single layer dielectric films of

ZnS (n = 2.3) and MgF2 (n = 1.35). How do these values compare with

those of a bare glass substrate (for glass, n = 1.5)?

, evaluate R and T for single layer dielectric films of

ZnS (n = 2.3) and MgF2 (n = 1.35). How do these values compare with

those of a bare glass substrate (for glass, n = 1.5)?

Question 2.2.

In general, for ![]() , what happens to R

and T if a single layer of thin film

on glass substrate exposed to air for:

, what happens to R

and T if a single layer of thin film

on glass substrate exposed to air for:

i)

n

of dielectric greater than nS?

ii)

n

of dielectric larger than nS?

Substitute

some values of different dielectric materials and verify. Consult Chopra page

750 Table III for refractive indices of some common materials used in thin

film.

Question 2.3.

Repeat question 2.2 for ![]() and

and ![]()

Multilayer All-dielectric Thin Film

Now consider the situation where there are N dielectric layers coated above the

substrate. The layers are labeled {1,

2, 3 … N}. They have indices

of refraction {n1, n2, n3 … nN}

and thicknesses {d1, d2, d3 … dN},

respectively. Similarly, the reflection and transmission coefficients of this

system are related by a matrix equation:

(11)

(11)

where Mi denotes the transfer matrix of the ith layer and the transfer

matrix Meffective is the

product of the transfer matrix of the various layers. All other properties

remain identical to the case of a single dielectric layer but making use of Meffective.

First consider a

double layer thin film composed of two dielectric materials, A and B. These two

adjacent layers have index of refraction nA

and

![]()

So the thickness of each layer can be calculated to be:

![]() (12)

(12)

In this case, using equation (8) and (11), the transfer matrix is found

to be:

Now consider a stack of alternating layers of dielectric A

and dielectric B. If there are N pairs of such double layer dielectrics, the

transfer matrix becomes:

Now consider a stack of alternating layers of dielectric A

and dielectric B. If there are N pairs of such double layer dielectrics, the

transfer matrix becomes:

Substituting this result into equation (9) one can find the reflection

coefficient to be:

It is easy to verify that, with the increase of N, R approaches unity if nA and nB are different. Consequentially, a stack of

quarter-wavelength alternating dielectric layers forms a high-reflectance thin

film at a particular wavelength, λ0.

Question 2.4. How is the wave number k related to λ0?

Question 2.5. Verify that ![]() for quarter wavelength

thickness.

for quarter wavelength

thickness.

Question 2.6.

For an 8-layer high reflectance thin

film composed of alternating ZnS and MgF2 on glass substrate, sketch

a plot of the reflectance versus number of deposition layers, quantitatively

indicating the local minimums and maximums. How would the plot change if MgF2

is deposited first rather than ZnS? In either case, what is the net change of

reflectance? As you can see, even for small value of N, theory predicts a reflectance close to unity.

Question 2.7. A beam of white light falls at normal

incidence on a plate of glass of index n and thickness d. Show that minimum

reflectance occur at those wavelengths such that ![]() , where λ0

is the vacuum wavelength and N is an integer. This means that reflection and

transmission functions are periodic with respect to wavelength and this is

called a channeled spectrum.

, where λ0

is the vacuum wavelength and N is an integer. This means that reflection and

transmission functions are periodic with respect to wavelength and this is

called a channeled spectrum.

Fabry-Perot Filter?

Description needed.

3. Deposition Technique

Operation under Vacuum

The multilayer thin film is to be fabricated under vacuum

in this experiment. Before beginning, read the write-up for the second-year

laboratory “Evaporation of Silver Films” for a thorough understanding of the

components of a vacuum system and the evaporation process. Do not worry about

the thickness estimation methods since a different one will be used. Become

familiar with the operation of the Edwards High Vacuum System used in this

experiment.

The Photometric Method

For dielectric films deposited on a transparent substrate

of a different refractive index (glass is used in this experiment), the optical

reflectance and transmittance behavior of the film-substrate combination, at

fixed wavelength of incident light, shows an oscillatory behavior as a function

of film thickness because of interference effects. Recall from question 2.2,

reflectance is reduced or enhanced depending on the relative values of

refractive indices of the film and the glass substrate.

The setup of photometric monitoring is summarized in the

diagram below, consult Chopra page 99 and explain the functionality of the

method.

Figure 2. The photometric monitoring setup.

In this setup, the reflected light passes by a bandpass

filter so that a short range of wavelength is monitored by the detector.

Question 3.1. How can one achieve the same

functionality without using a bandpass filter?

Question 3.2.

Use the spectroscopy described in section 4, measure the visible

wavelength range transmission spectrum of the filter used in the above setup.

How good is this filter?

Question 3.3.

What are some limitations to the photometric method? What happens with

increasing number of layers deposited?

Determining the film thickness

Film thickness is related to and can be determined from

the maxima and minima of the reflectance which occur at intervals given by (Chopra,

page 99)

![]() [13]

[13]

where m is the order of the maximum or minimum and all other variables as

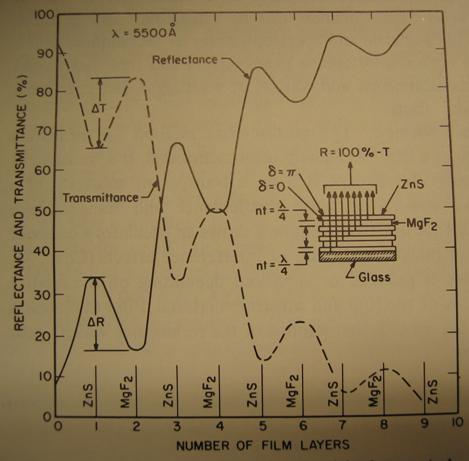

previously defined. The illustration below shows the observed variation of the

reflectance and transmittance of alternating ZnS and MgF2 quarter

wavelength films.

Figure 3. Reflectance and Transmittance of increasing number

of multilayers

Steckelmacher et al., Vacuum, 9:171

(1959)

Question 3.4.

Show that, after two maxima or minima are traversed (first being the

value at zero deposition), thickness for a single layer film is quarter

wavelength. (Hint: consider equation (12)).

Therefore by monitoring maxima and minima while depositing,

the thickness of each film is controlled to be quarter wavelength.

Question 3.5.

Calculate the actual thickness of quarter wavelength layers of ZnS, MgF2,

and cryolite (Na3AlF6) if blue light is monitored.

Question 3.6.

Make predictions to the shape of the channel spectrum with respect to

the filter used, indicating quantitatively the critical points.

3. Evaluating Optical Properties of Your Film

The

spectrometer consists of a wavelength dispersive device and a photomultiplier.

A prism is used to pick out photons of specified wavelength and transmit them

to the photomultiplier. A mechanical system of gears and springs attached to

the prism is adjusted to vary the specified wavelength. With your multilayer

thin film at the slit opening, obtain transmission spectra by scanning through

the visible wavelengths of light. (Hint: overlay the spectra on top of a white

light source spectrum for ease of comparison.)

The Photomultiplier

Photomultipliers are extremely sensitive detectors of

light, or photons. Incident photons strike the cathode material, and produce

electrons as the result of photoelectric effect. These electrons are

accelerated towards the electrode, while undergoing the process of secondary

emission. Secondary emission effectively

multiplies the electron signal. The electron multiplier consists of numerous

small electrodes called dynodes. Each dynode is held at a positive voltage with

respect to the previous one. When electrons leave the photocathode, they have

the energy of the incoming photon. While traveling towards the first dynode,

the electrons gain energy from the electric field. On arriving at the dynode

with much greater energy, the electrons can cause emission of low energy

electrons. The original electrons from the cathode, together with the newly

generated low energy electrons, then are accelerated toward the second dynode.

This process repeats and a cascading effect occurs, which result in a high

accumulation of charge arriving at the anode. This effect induces a sharp

noticeable current pulse in the device even if only a single photon enters the

cathode.

Measure the channel spectrum of your multilayer thin film

in the visible wavelength.

Question 4.1.

Compare and contrast the measured channel spectrum with respect to

theoretical predictions.

Question 4.2.

How does the slit width of the spectrometer affect the shape of your

spectra? What is a suitable slit width to yield a representative spectrum?

Question 4.3.

With a narrow slit width (approximately 1000 µm), take spectra of your

thin film at different positions on the thin film. Does this have an effect on

the shape on the channel spectrum? If so, is it understandable? What part of

the experiment most likely resulted in such changes in the channel spectrum?

Question 4.4.

How would incident light at different angles affect the channel

spectrum?

Some Discussion Questions

1.

What is a

Fabry-Perot Filter? Describe its functionality and composition

2.

Why might one

wish to use MgF2 instead of cryolite in making thin films with ZnS?

3.

How does the

addition of a silver deposition layer on top of the multilayer high reflectance

thin film affect its performance? You may wish to add a silver deposition layer

and contrast the channel spectrum from before and after.

4.

In an one-way

mirror, the metallic/dielectric coatings on the surface of glass substrate

actually result in a so called “half-layer” thin film. This just means that

neither of transmittance nor reflectance is very high or very low. Then how

does an one-way mirror work? (Hint: think about the slit width and the white

light source in the spectroscopy section)

References

1) Chopra, K.L.

(1969). Thin film phenomena.

2) Fowles, G.R. (1975).

Introduction

to modern optics. 2nd

ed.

3) Hecht, E. (2002).

Optics. 4th ed.